Innovation & Process: Speed, Precision and Partnership

At Reelvision Print, we don’t just print cartons – we engineer your time-to-market advantage. Our entire operation, from design consultation to delivery, is built on cutting-edge innovation and a streamlined process to ensure superior quality and industry-leading speed.

At Reelvision Print, we don’t just print cartons – we engineer your time-to-market advantage. Our entire operation, from design consultation to delivery, is built on cutting-edge innovation and a streamlined process to ensure superior quality and industry-leading speed.

Technical Edge: Single-Pass Production

Our investment in the latest print technology is what sets us apart, allowing us to deliver complex, high-quality packaging with exceptional efficiency.

High-Efficiency Flexo Press

We utilise advanced flexographic (flexo) printing presses that embody efficiency and precision. These machines are the cornerstone of our rapid production capability.

Single-Pass In-Line System:

Our press is configured to handle multiple stages – printing, varnishing, and die-cutting – all in a single, uninterrupted pass. This in-line process eliminates the time, risk, and material waste associated with moving partially finished jobs between different machines.

Benefits:

- Maximum Speed: Drastically reduces total production time.

- Perfect Registration: Guarantees absolute alignment between printed graphics, special effects, and the final cut shape.

- Cost Efficiency: Streamlines operations,helping us pass savings on to you.

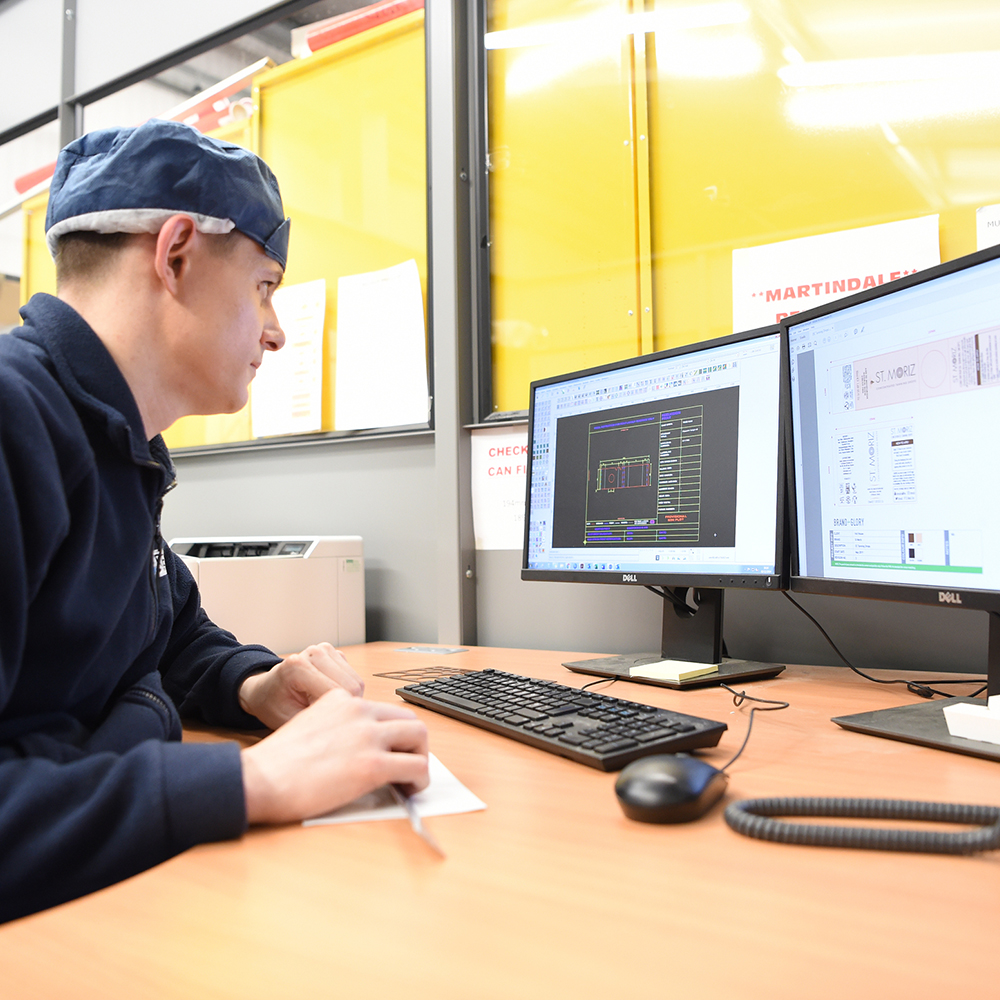

Accelerated Design: 48-Hour CAD Service

Speed in manufacturing starts with speed in design. Our dedicated in-house Computer-Aided Design (CAD) team works as an extension of your brand, turning concepts into physical prototypes with unmatched swiftness.

Custom Packaging Solutions in 48 Hours

We understand that time is critical during product development. Our process is designed to deliver a complete, testable solution in just two days.

Collaborative Design:

Our team of experts consult with you to understand your product dimensions, carton style needs (e.g., reverse tuck end, crash lock base), and specific performance requirements.

Precision CAD Creation:

We generate precise digital die-lines and 3D mock-ups to visualise the final structure.

Rapid Prototyping:

Crucially, we can provide a physical, precision-cut prototype within 48 hours of receiving your brief. This sample allows you to test the fit, structural integrity, and packing line compatibility before committing to a final print run.

The Reelvision Print Speedy Process

Our entire workflow is engineered for speed, providing you with certainty and reliability from initial contact to final delivery. From the moment you approve the final design and artwork proof, your packaging production moves into our accelerated manufacturing pipeline, guaranteeing a 10-day turnaround (delivery) on standard orders.

1. Customer Enquiry

Initial needs assessment, consultation, and quotation.

2. Design & CAD

Structural design, 3D render, and physical prototype creation.

3. Proof Approval

You approve the final structure and artwork files. (Start of 10-Day Clock).

4. Print & Production

Single-pass flexo printing, finishing (e.g., UV coating), and cutting.

5. Gluing & Packing

Cartons are folded, glued, and packed for dispatch.

6. Delivery

Your finished, high-quality cartons arrive at your door.

We remove the guesswork and delays that plague traditional packaging suppliers.

By combining in-house structural expertise (CAD), immediate access to premium Holmen Iggesund board stock, and our efficient single-pass press technology, we deliver speed without ever compromising on the finished quality of your brand's packaging.