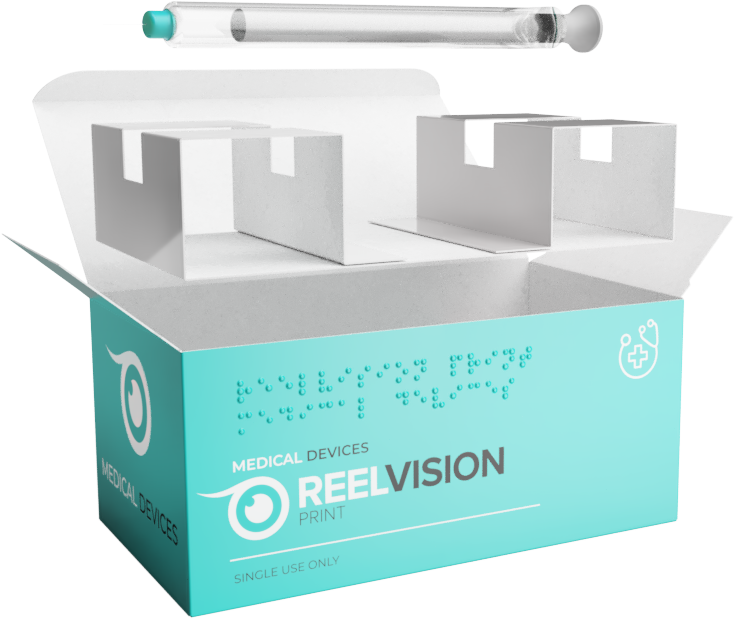

Medical Devices & Woundcare Packaging

Secure folding cartons for medical devices

The Medical Devices and Woundcare market demand absolute packaging security, regulatory compliance, and manufacturing quality control. Reelvision Print specialises in delivering these critical requirements with ISO-standard quality management, offering no minimum order volumes for your sterile barrier packaging components.

Our flexo printing process ensures flawless print legibility for critical information and utilises security features to prevent counterfeiting. This process facilitates short-run packaging and rapid turnaround, essential for managing product recalls, device upgrades, and dynamic clinical trial needs.

Why choose Reelvision Print for Medical Packaging?

At Reelvision Print, we specialise in compliant folding cartons with a fast-turnaround service, custom-designed to meet stringent MHRA standards, ensuring product safety and traceability:

Medical & Surgical Device Cartons

High-quality, durable secondary packaging for sterile devices, kits, and instruments. Designed for secure closure, tamper-evidence, and high legibility of UDI (Unique Device Identification) barcodes.

Woundcare Packaging Sleeves

Printed sleeves and outer wraps that provide an essential protective and security layer for primary containers of dressings, swabs, and bandages, maintaining their integrity until the point of use.

Clinical Trial & Sample Packaging

Custom-designed cartons that ensure traceability and compliance for devices used in clinical investigations, managing serialised information and protecting sensitive trial products.

Quality, Traceability & Compliance

Partnering with Reelvision Print for your medical device folding cartons means you secure a supply chain partner committed to the highest standards of quality and regulatory assurance for your critical products.

FSC® Certified Materials:

Commitment to sustainably sourced paperboard to meet corporate environmental and social governance goals.

Rapid Lead Times:

Fast-turnaround service meets dynamic supply chain demands and urgent regulatory packaging changes.

Flawless Colour Consistency:

Ensures zero visual variation between product batches, which is critical for warning colours and regulatory markings.

PS9000 Certification:

Guarantees strict adherence to the pharmaceutical quality management system for secondary packaging, demonstrating high commitment to safety.

Provides essential product information for visually impaired consumers, meeting crucial regulatory requirements while demonstrating commitment to inclusivity.

Custom-cut trays, dividers, or inserts that hold the product securely in place and prevent movement.

Perfect colour matching across all batches, critical for patient safety, quick identification, and compliance with national warning colour standards.